Pressure Granular Media Filters

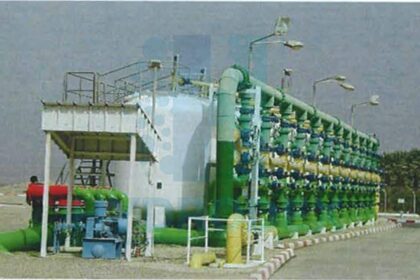

Pressure filters have filter bed configuration similar to that of gravity filers, except that the filter media is contained in steel pressure vessel. They have found application mainly for small and medium size seawater desalination plants – usually with production capacity of less than 20,000 m3/day. An exception is Spain, where practically all of the pretreatment filters at seawater desalination plants are pressure filters. In most cases for good source seawater quality (SDI < 5 and turbidity less than 5 NTU) the pressure filters are designed as single stage, dual media (anthracite and sand) units. Some plants with relatively poor water quality use two-stage pressure filtration systems. Pressure filters are available in two vessel configurations – vertical and horizontal. Vertical pressure filters (see Figure 15) are customarily used in smaller plants and individual vessels have maximum diameter of 3 m. Horizontal pressure filters (Figure 16) are used more frequently in desalination plants and are more popular for medium and large-size facilities. The largest desalination plant using horizontal pressure granular media filters for seawater pretreatment is the 160,000 m3/day Kwinana SWRO facility in Perth, Australia (see Figure 17). Horizontal filters allow larger filtration area per filter vessel as compared to vertical units. However, usually vertical vessels can de designed with deeper filter media, if deep filters are needed to handle spikes of source seawater turbidity.

Pressure Single-Stage Dual-Media Filters-Key Design Criteria

Compared to gravity media filters, which operate under a maximum water level over the filter bed of up to 2.5 meters, pressure filters typically run at feed pressure equivalent to 15 to 30 meters of water column. The magnitude of the feed pressure is often driven by the suction pressure requirements of the high pressure feed pumps of the downstream SWRO system. One key advantage of the pressure filters is that they could allow avoiding intermittent pumping of the pretreated seawater. A typical SWRO

system with gravity pretreatment filters requires installation of filter effluent transfer pumps to convey the filtrate from the filter effluent well to the high pressure SWRO feed pumps. Use of pressure filters could eliminate the need for such interim filter effluent transfer pumps because the filtrate is already pressure-driven by the intake pumps and the pretreatment filters do not break the hydraulic grade line.

Key design criteria for single-stage dual media pressure filters in small and medium size desalination plants are very similar to these of gravity filters. Design criteria by which pressure filers differ for gravity filters are presented below:

| Number of Filter Vessels | 6 to 20 |

| Filter Vessel Diameter | 1.2 to 6m (typically 3m) |

| Filter Vessel Length 2.5 to 15 m (typically 6 m) | Filter Vessel Length 2.5 to 15 m (typically 6 m) |

| Depth of Filter Bed | 0.6 to 0.9m |

| Filtration Rate (at Desalination Plant Intake Design Flow) | |

| With All Filters in Service | With All Filters in Service |

| Head loss Across the Filter Vessel | |

| Total Headless Across the Filter | 15 to 30m (20m average) |

| Net Headless Available for Filtration | 7.5 to 15m |

Horizontal Single Stage Granular Media Filter Pressure Vessel Made of Steel in Kwinana SWRO, Australia

Horizontal Granular Media Filter Pressure Vessel Made of Steel

Vertical Granular Media Filter Pressure Vessel Made of Steel

The design criteria presented above are guidelines – media size, depth and configuration, especially for medium and large desalination plants, are recommended to be selected based on pilot testing for the site specific conditions and water quality associated with the project.