Reverse Osmosis RO Membrane Particle Fouling Reverse Osmosis RO Membrane Particle Fouling is caused by organic and inorganic particles contained in the source seawater such as fine debris, plankton, detritus and silt, which cannot pass through the SWRO membranes. All suspended solids which naturally occur in insoluble form, if not removed by pretreatment, would be

- Published in Filter

Reverse Osmosis RO Membrane Colloidal Fouling Reverse Osmosis RO Membrane Colloidal fouling is caused by inorganic and organic compounds that naturally exist in suspension and may be concentrated by the SWRO desalination plant separation process, and precipitate on the Reverse Osmosis RO membrane surface thereby causing membrane flux decline over time. Colloidal solids have particle

- Published in Filter

Reverse Osmosis RO Membrane Mineral Scaling Reverse Osmosis RO Membrane Mineral Scaling Causes: All minerals contained in the source seawater are concentrated during the process of membrane salt separation. As their concentration increases during the desalination process, ions of Calcium, Magnesium, Barium, Strontium, Sulfate and Carbonate can form sparingly insoluble salts which could precipitate on

- Published in Filter

Reverse Osmosis RO Membrane Scaling and Fouling: Causes Reverse Osmosis RO Membrane Scaling and Fouling have many reasons which will be discussed in this article. First, we need to learn the mechanism of desalination plants. In desalination plants, Seawater is collected from the ocean using either subsurface intakes (wells, intake galleries, etc.) or open ocean

- Published in Filter

Advantages of Gravity Granular Multi Media Filters in SWRO Pre-treatment The advantages of gravity granular multi media filters as a pre-treatment in SWRO plants is simply for better removal of algal material from the Seawater. Seawater always contains a measurable amount of algae, which concentration usually increases several times during the summer period and may

- Published in Filter

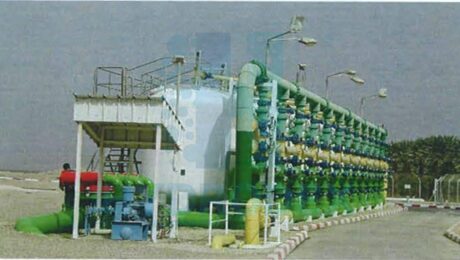

Pressure Granular Media Filters Pressure filters have filter bed configuration similar to that of gravity filers, except that the filter media is contained in steel pressure vessel. They have found application mainly for small and medium size seawater desalination plants – usually with production capacity of less than 20,000 m3/day. An exception is Spain, where

- Published in Filter

Gravity Granular Media Pretreatment Filters Design Calculations Gravity granular media filters are typically reinforced concrete structures that operate at water pressure drop through the media of between 1.8 m and 2.4 m. Single-stage dual media downflow gravity filters are predominant type of filtration pretreatment technology used in desalination plants of capacity higher than 40,000 m3/day.

- Published in Filter

What is the Difference Between Pleated, String Wound and Melt Blown Filter Cartridges? Each type of filter cartridges is acceptable for pretreatment to RO membranes. Pleated filter cartridge is typically used in higher purity applications such as pharmaceuticals and microelectronics. String wound filter cartridge is just as they sound; material such as polypropylene in string

- Published in Filter

- 1

- 2