What is the Difference Between Pleated, String Wound and Melt Blown Filter Cartridges?

Each type of filter cartridges is acceptable for pretreatment to RO membranes. Pleated filter cartridge is typically used in higher purity applications such as pharmaceuticals and microelectronics. String wound filter cartridge is just as they sound; material such as polypropylene in string form which is wound around a central core. The disadvantage of these filter cartridges is that they suffer form particle unloading at higher pressure drops and require a slower velocity through them than other types of filter cartridges. Typically 2-3 gpm per 10 inch equivalent rather than 5 gpm per 10 inch equivalent for pleated and melt blown filter cartridges. The melt blown variety is thermally bonded polypropylene microfibers and is typically denser near the core than at the outside.

Read more about Hydrodex different types of filter cartridge.

Spun PP – Melt-Blown Filter Cartridge

- Exceptional performance

- Long service life

- Lower energy and maintenance costs

- Low initial pressure drop

- Deliver high efficiency and consistent filtration of fluids in a wide range of critical applications

Features

- Cartridges are constructed of microfiber (spun PP) melt-blown media to provide high area, surfactant-free and non-fiber releasing filtration.

- Multi-layered filter media is optimized for high efficiency particle removal and high contaminant holding capacity resulting in longer on-stream life cycles.

- 100% polypropylene materials provides wide chemical compatibility with acids, bases, salts, and most organic solvents. The high quality construction facilitates quick cleaning for reuse if desired.

- Durable, thermal bonded construction ensures cartridge integrity under severe operating conditions. No adhesives, binders, lubricants, or anti-static agents are used in the manufacturing process.

- Full range of micron levels.

- FDA compliant materials.

Specifications

- Micron Ratings: 0.6, 1.2, 2.5, 5.0, 10, 20.

- 50 μm absolute

- Dimensions: 2 1/2” OD

- Length: 10, 20, 30 & 40’’

- Maximum Temperature: 185° F (85° C)

Construction

- Media: Polypropylene

- Support Layer: Polypropylene

- Core, Cage, End Caps: Polypropylene

- Gaskets/O-Rings: Ethylene Propylene, Silicone,

- Buna-N, Neoprene, Teflon, Viton

Service

- Leading industry knowledge.

- Quick order turn-around.

- Exceptional customer service.

- Bring us your application and we will help you find the cartridge you need.

- Quick order turn-around.

- Bring us your application and we will help you find the cartridge you need.

Applications

- Food and Beverage Processing

- High Purity Chemicals

- RO Pretreatment

- Cosmetics and Fragrances

- Chemical Mechanical Polishing

- Photographic Solutions

- Metal Finishing/Plating Solutions

- Solvent Filtration

- Paints and Coatings

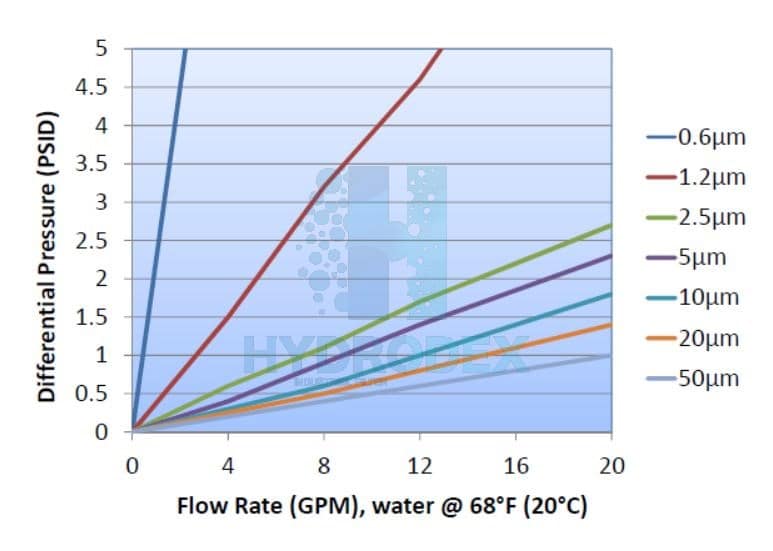

Liquid Flow Rate vs. Pressure

Hydrodex spun pp melt blown liquid flow rate vs pressure

Explore our other filters